Welding and machining

Machining

HORIZONTAL BORING MACHINE WFT 13

Workpieces up to 12 tons weight. IT 7 machining accuracy, work-piece maximum dimensions: 2,5 x 2 x 4m.

Gearboxes, machine frames, dampers, ball valves, 2,5 D forms, turbines, wind turbine propellers, weldments, castings, forgings, material: stainless steel, steel of all classes, aluminium, cast iron, Cu irons.

HORIZONTAL BORING MACHINE W100

Workpieces up to 3,5 tons weight. IT 7 machining accuracy, work-piece maximum dimensions: 1 x 1,2 x 2 m.

Gearboxes, machine frames, dampers, ball valves, forms, turbines, weldments, castings, forgings, material: stainless steel, steel of all classes, aluminium, cast iron, Cu irons.

MACHINING CENTER WMCF 1600

Workpieces up to 5 tons weight. IT 7 machining accuracy, work-piece maximum dimensions: 0,9 x 0,7 x 1,5 m.

2,5 D Forms, gearboxes, armatures, shaft splines, drilling precise holes, material: stainless steel, steel of all classes, aluminium, cast iron, Cu irons

VERTICAL TURRET LATHE VLC 1600

Workpieces up to 8 tons weight. IT 7 machining accuracy, work-piece maximum dimensions diameter: 1,8 x 1,4 m. Minimal weight of workpiece is 100 kg.

Rotary and eccentric components, bodies of armatures, drive wheels, forms, turbines, diffusers, cases, sliding bearings, electric motors-housings, housings of pressure bottles, roller crushers, pistons, hydraulic cilinder heads, material: stainless steel, steel of all classes, aluminium, cast iron, Cu irons.

LATHE CU 1000RD

Workpieces up to 6 tons weight. IT 7 machining accuracy, work-piece maximum dimensions diameter: 0,59 x 6m. After removing the bridge dimension diameter 1,2 x 0,3 m. Minimal weight of workpiece is 50 kg.

Rotary and eccentric components, bodies of armatures, drive wheels, forms, turbines, diffusers, cases, sliding bearings, electric motors-housings, housings of pressure bottles, roller crushers, pistons. Hydraulic cilinder heads, plungers, rods of drilling systems, calibration cylinders, torsion bars, shaft flangers, material: stainless steel, steel of all classes, aluminium, cast iron, Cu irons.

SPIKE LATHE SA 102/6000CNC

Workpieces up to 6 tons weight. IT 7 machining accuracy, circumferential diameter 1020 mm. Circumferential diametrt above the support 680 mm, working lenght between spikes 5800 mm, minimal weight of workpiece is 50 kg.

Rotary and eccentric components, bodies of armatures, drive wheels, forms, turbines, diffusers, cases, sliding bearings, electric motors-housings, housings of pressure bottles, roller crushers, pistons. Hydraulic cilinder heads, plungers, rods of drilling systems, calibration cylinders, torsion bars, shaft flangers, material: stainless steel, steel of all classes, aluminium, cast iron, Cu irons.

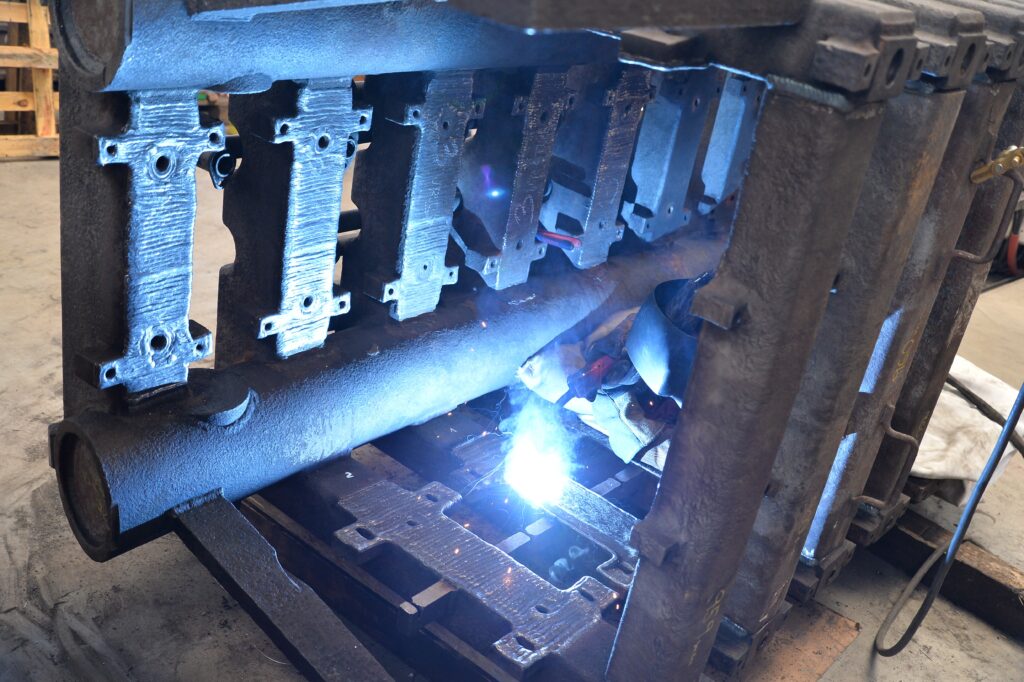

Welding

Our welding building is engaged in three basic activities. Renovations of manufactured weldments using semi-automatic or manual welding. Renovation of piston rods with micro welds and complete production of new weldments according to our own or supplied documentation.

CaB 400 SEMI-AUTOMATIC WELDING

Rotary weldments from diameters 200 to 4000 mm, lengths up to 10 m, weight from 50 kg to 12 tons, pressure bottles, turbines, wind power towers, hot water tanks, valves, ball caps, welding of calibration cylinders, conveyor belt cylinders, crushing cylinders of cement plants and quarries, drilling rods of oil systems, filters, guide rails. Submerged arc and MIG , MAG welding methods, welding wires up to 4 mm diameter, single, twin, tape 30 mm, stainless steel material, steel grade 11.12.15.

MANUAL WELDING

Methods: MIG MAG, Argon, electrode

Products up to 12,5 tons, size 5x5x10 m

Gearboxes, valves, machine skeletons, pressure bottles, heat exchangers, pipelines, buckets for excavators and dredgers, welded structures, shredder designs, refurbishment of rollers, shafts and housings of smaller dimensions, material: stainless steel, steel of 11,12,15 grade, cast iron, aluminium.

MICRO-WELDING

Replacement of piston rods and parts with relatively small extent of damage – dents and scratches. The repair is carried out by welding (dripping) the missing material and then polishing to the original state.

Testing room for mechanical and hydraulic equipment

BASIC EQUIPMENT OF THE TESTING ROOM

- Overhead crane with a lifting capacity of 25 000 kg

- maximum floor load 6 000 kg/m2

- Assembly pit dimensions (ØL x H) Ø2.8 x 3.5 m

- Entrance No. 1 with dimensions (W x H) 3.5 x 3.5 m

- Entrance No. 2 with dimensions (W x H) 4.4 x 4.2 m

1) HYDROMECHANICAL LOADING EQUIPMENT FOR TESTINIG THE PRESSING PROCESS

Technical parameters:

- Maximum tensile load force 1 MN

- Maximum load force in compression 2 MN

- Maximum speed of movement in tension 0,05 m/s

- Maximum speed of movement in compression 0,05 m/s

- Maximum stroke 1 000 mm

2) TEST PLATE FOR MACHINE CLAMPING

Technical parameters:

- Dimensions 6 x 5 m

- Maximum load 35 000 kg/m2

3) HYDRAULIC STATION FOR SUPPLYING TEST SITES

Parameters in the main circuit:

- Installed power 90 kW

- Maximum operating pressure 320 bar

- Maximum flow 267 dm3/min

Parameters in the control circuit:

- Installed power 15 kW

- Maximum operating pressure 200 bar

- Maximum flow 41 dm3/min

Parameters in the high pressure circuit:

- Installed power 1,5 kW

- Maximum operating pressure 500 bar

- Maximum flow 1,5 dm3/min

4) HYDRAULIC STAND FOR TESTING HYDRAULIC COMPONENTS, HYDRAULIC MOTORS AND CONTROL ASSEMBLIES

Hydraulic parameters:

- Maximum operating pressure 320 bar

- Maximum control pressure 200 bar

- Maximum test pressure 500 bar

- Maximum flow rate 267 dm3/min

Electric parameters:

- Solenoid valve power supply 24 VDC

- Control of proportional valves ±10V, 4 – 20mA

- Measuring outputs from sensors 0 – 10V, 4 – 20mA, SSI

5) TEST POWER SWITCHBOARD WITH POWER CONSUMPTION MEASUREMENT

Electric parameters:

- Maximum power consumption 400 kW

- Power supply for three-phase electric motors 400VAC/50Hz

- Connection of electric motors (with reversing option) with outputs 0,09 – 0,75 kW

- Connection of electric motors (with reversing option) with outputs of 0,55 – 3 kW

- Connection of electric motors (frequency controlled) with outputs 3 – 22 kW

- Connection of electric motors (frequency controlled) with outputs 22 – 90 kW

All of the above mentioned equipment and services are now provided to customers as a very specific service, either in the form of turnkey testing or in the form of renting the premises for the purpose of testing. Possible forms of cooperation can be consulted at the contact below.